Introduction

Rolex is more than a luxury label; it represents uncompromising Swiss precision and elegance and is designed, machined, assembled and tested under one roof. Four Swiss sites—Plan‑les‑Ouates, Chêne‑Bourg, Bienne and Geneva—employ more than 9,000 craftsmen to create cases, movements, dials and bracelets. Consequently, a Rolex is not just a timekeeper but an enduring work of art.

The Rolex Philosophy of Excellence

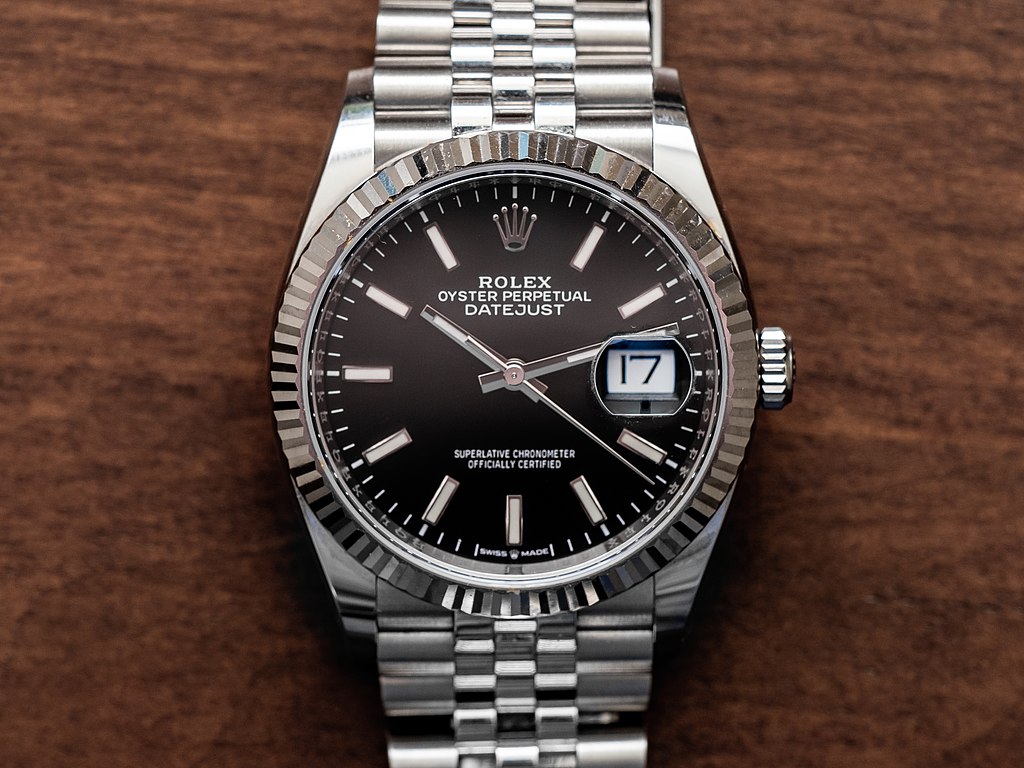

The phrase “Superlative Chronometer” expresses Rolex’s quest for precision, durability and innovation. The brand established its own certification in the 1950s and updated it in 2015 so that every watch surpasses the industry‑wide COSC standard. Encased movements must run within –2/+2 seconds per day and show flawless self‑winding, water‑resistance and power‑reserve performance, meaning Rolex demands twice the accuracy required by other chronometers.

Durability is equally important. Rolex developed Twinlock and Triplock crowns to seal out dust and moisture and devised the Oyster case—the first waterproof wristwatch case—with a screw‑down bezel, case back and crown. Continuous testing ensures these systems maintain reliability for decades.

Materials and Innovation

Rolex controls metal quality by casting its own alloys in an in‑house foundry. The 904L Oystersteel resists corrosion and retains shine, while Rolesor blends steel and gold for two‑tone watches. The brand also melts 18‑karat yellow, white and Everose gold by mixing pure gold with silver, copper and palladium or indium to achieve lasting hues.

Movement Production

At the Bienne site, Rolex assembles 200–400 components into reliable movements. Its patented Perpetual rotor captures wrist movement to deliver up to a 72‑hour power reserve. Innovations like the Parachrom hairspring, which resists magnetism and temperature variations, and the 2015 Chronergy escapement, which optimizes energy transfer at 28,800 beats per hour, ensure efficiency and stability.

The Art of Case and Bracelet Crafting

Every Rolex case starts as a bar of metal machined to micron tolerances. The patented Oyster case seals the watch with a screw‑down bezel, back and crown. Specialised Triplock crowns resist deep‑sea pressures, while helium escape valves protect professional divers.

Bracelets vary to suit the wearer. The classic Oyster uses three‑piece links for strength and comfort; the Jubilee, introduced in 1945, has a woven five‑piece pattern; the President offers semi‑circular links in precious metals; and the sporty Oysterflex combines elastomer with a metal blade. Each component is hand‑polished, proving that craftsmanship remains central to Rolex.

Rolex Laboratories and Quality Testing

Before leaving Geneva or Bienne, each watch is immersed in hyperbaric chambers to test waterproofness and pounded by machines simulating thousands of shocks. Encased movements must meet –2/+2 seconds daily accuracy and prove power reserve and self‑winding performance before earning the Superlative Chronometer seal.

Handcraft Meets Technology

Rolex relies on robots and artisans in equal measure. Robots retrieve components from secure vaults and deliver them along automated belts, and CNC machines cut metal with sub‑micron accuracy. However, final assembly remains in human hands. In Bienne, watchmakers adjust balance wheels, oil jewels and regulate escapements under loupes and microscopes. Each movement is assembled and signed off by one craftsman, ensuring accountability and blending technology with tradition.

Final Assembly and Quality Control

Final assembly occurs at the Acacias headquarters in Geneva, where cases, bracelets, dials and movements converge in dust‑free rooms. Technicians fit hands and bracelets and perform final accuracy, waterproof and power‑reserve tests before awarding the green seal. At Plan‑les‑Ouates, iris scanners and underground vaults protect precious metals, and finished watches are shipped discreetly through authorised retailers.

Conclusion

Rolex’s manufacturing process is a testament to Swiss excellence. From proprietary alloys like Oystersteel and Everose gold to cutting‑edge hairsprings and escapements, every element is designed to outlast trends and generations. Each watch passes through hundreds of hands and dozens of machines before earning the green seal of Superlative Chronometer, which explains why a Rolex commands such admiration and holds its value.

Owning a Rolex is not merely purchasing a watch—it is investing in a piece of horological heritage. Knowing that your timepiece was forged, assembled and tested under the strictest Swiss standards deepens the emotional connection and ensures your Rolex will continue to mark life’s moments with precision and elegance.