Key Takeaways:

- Richard Mille uses aerospace-grade materials (Carbon TPT®, Quartz TPT®, Grade 5 Titanium)—not “plastic” as critics claim

- Extreme pricing ($300,000+) reflects manufacturing difficulty, rejection rates up to 50%, and annual production under 6,000 watches

- Unlike traditional brands, RM watches withstand forces up to 14,000 g’s—worn during competition, not after

- The brand generates $1.77 billion in revenue from just 5,700 watches annually, averaging $310,000 per piece

The Richard Mille Phenomenon: “A Racing Machine on the Wrist”

Disruption of Tradition: Challenging the Patek/Rolex Status Quo

When Richard Mille launched his eponymous brand in 2001, the luxury watch industry operated under centuries-old assumptions. Patek Philippe represented heritage and hand-finishing. Rolex symbolized durability and precision. Both championed polished gold, traditional complications, and watchmaking reverence for history.

Richard Mille rejected all of it. Instead of gold, he chose carbon composites from Formula 1. Instead of chronographs and perpetual calendars, he engineered shock resistance systems inspired by aerospace engineering. Instead of polished elegance, he celebrated skeletonized movements and sandblasted titanium. The watch world responded with horror, fascination, or both.

The Philosophy: Function Over Polish, Performance Over Heritage

Richard Mille’s founding philosophy centers on a simple declaration: “A racing machine on the wrist.” Every design decision prioritizes performance metrics—weight reduction, shock resistance, magnetic immunity, thermal stability—over traditional horological aesthetics. The watches look unfinished because they are unfinished by traditional standards. Polishing adds weight. Gold adds unnecessary mass. Heritage complications add fragility.

This philosophy manifests in watches that weigh as little as 11.5 grams (RM 27-05) yet withstand forces exceeding 14,000 g’s—accelerations that would pulverize traditional mechanical watches instantly. For context, fighter jet pilots experience approximately 9 g’s during combat maneuvers. Richard Mille builds watches that survive forces 1,500 times greater.

Why the Controversy? “Ugly/Overpriced” vs. “Futuristic/Ingenious”

The debate rages between traditional collectors and modern enthusiasts. Critics view Richard Mille watches as overpriced marketing exercises—expensive because celebrities wear them, not because they represent genuine horological achievement. They point to the unfinished aesthetic, the absence of traditional complications, and prices exceeding half a million dollars for time-only pieces.

Supporters counter that Richard Mille represents watchmaking’s evolution from jewelry to engineering. They argue that Carbon TPT® requires more sophisticated manufacturing than gold polishing, that shock resistance engineering surpasses perpetual calendar complexity, and that wearing a mechanical watch during professional tennis represents horological bravery unmatched in the industry.

The “Plastic” Myth: Analyzing Richard Mille Materials

Understanding Carbon TPT® and Quartz TPT®: Composite Engineering, Not Plastic

The most persistent misconception about Richard Mille watches is that they’re made from “plastic.” This fundamentally misunderstands composite material science.

Carbon TPT® (Thin Ply Technology) consists of hundreds of layers of parallel carbon fibers, each layer measuring approximately 45 microns thick (roughly half the thickness of human hair). These layers are impregnated with resin, stacked at alternating 45-degree angles, then cured in an autoclave at 120°C under 6 bar pressure (87 psi). The resulting composite achieves strength-to-weight ratios impossible with traditional metals.

Originally developed for Formula 1 chassis and racing yacht sails, Carbon TPT® offers:

- Exceptional tensile strength comparable to titanium

- 30% lighter weight than aluminum

- Superior vibration dampening versus metal alternatives

- Unique visual aesthetics where layered fibers create distinctive patterns

- Resistance to temperature extremes and UV degradation

Quartz TPT® takes this further by using fused silica fibers (purified quartz crystals drawn under oxy-hydrogen flame into continuous filaments). These quartz layers, interspersed with Carbon TPT®, create a material that:

- Remains transparent to electromagnetic waves

- Offers exceptional resistance to high temperatures

- Is completely non-allergenic and doesn’t yellow with UV exposure

- Enables true color integration into the resin matrix

- Won the JEC World 2016 Innovation Award for composite excellence

The manufacturing partnership with North Thin Ply Technology (NTPT) represents collaboration between Swiss watchmaking and cutting-edge material science. The automated layering machines can align fibers down to one degree of rotation for extreme aerospace applications—precision that rivals traditional watchmaking tolerances.

Grade 5 Titanium and Graphene: Why These Materials Skyrocket Manufacturing Costs

Beyond composites, Richard Mille extensively uses Grade 5 Titanium (Ti-6Al-4V alloy)—an aerospace-standard material offering:

- Exceptional strength combined with 45% lower density than stainless steel

- Resistance to extreme temperatures (-200°C to +600°C)

- Superior corrosion resistance in harsh environments

- Biocompatibility (the same titanium used in medical implants)

Grade 5 Titanium costs approximately 10 times more than 316L stainless steel and requires specialized CNC machining equipment. The material’s hardness destroys cutting tools rapidly, dramatically increasing manufacturing expenses.

Richard Mille also pioneered Gold Carbon TPT®, alternating carbon composite layers with 10-micron-thick gold leaf—a hybrid material combining carbon’s strength with gold’s nobility. Developing this required three years of research and manufacturing tolerances measured in microns.

The Cost of Failure: High Rejection Rates in Manufacturing

Perhaps the most overlooked aspect of Richard Mille’s pricing is manufacturing rejection rates. During early carbon baseplate development, the brand discarded 99 out of 100 pieces to achieve acceptable quality standards.

Even today, machining Carbon TPT® and Quartz TPT® cases carries significant risk:

- The angled layers become extremely vulnerable at edges during CNC machining

- Delamination (layers separating) can occur if cutting parameters aren’t perfect

- Each case blank requires hours of precision CNC work from a solid block

- Rejected cases represent total material and labor losses

For titanium components, the challenges multiply. A single kilogram of Richard Mille’s precision-machined titanium screws (requiring nine different hand-finishing techniques) costs approximately CHF 1,000,000 ($1.1 million USD)—demonstrating the extreme cost of achieving aerospace-grade tolerances in luxury watchmaking.

Horological Legitimacy: Is the Movement Technology Real?

Shock Resistance Mastery: The Rafael Nadal (RM 27-04) Case Study

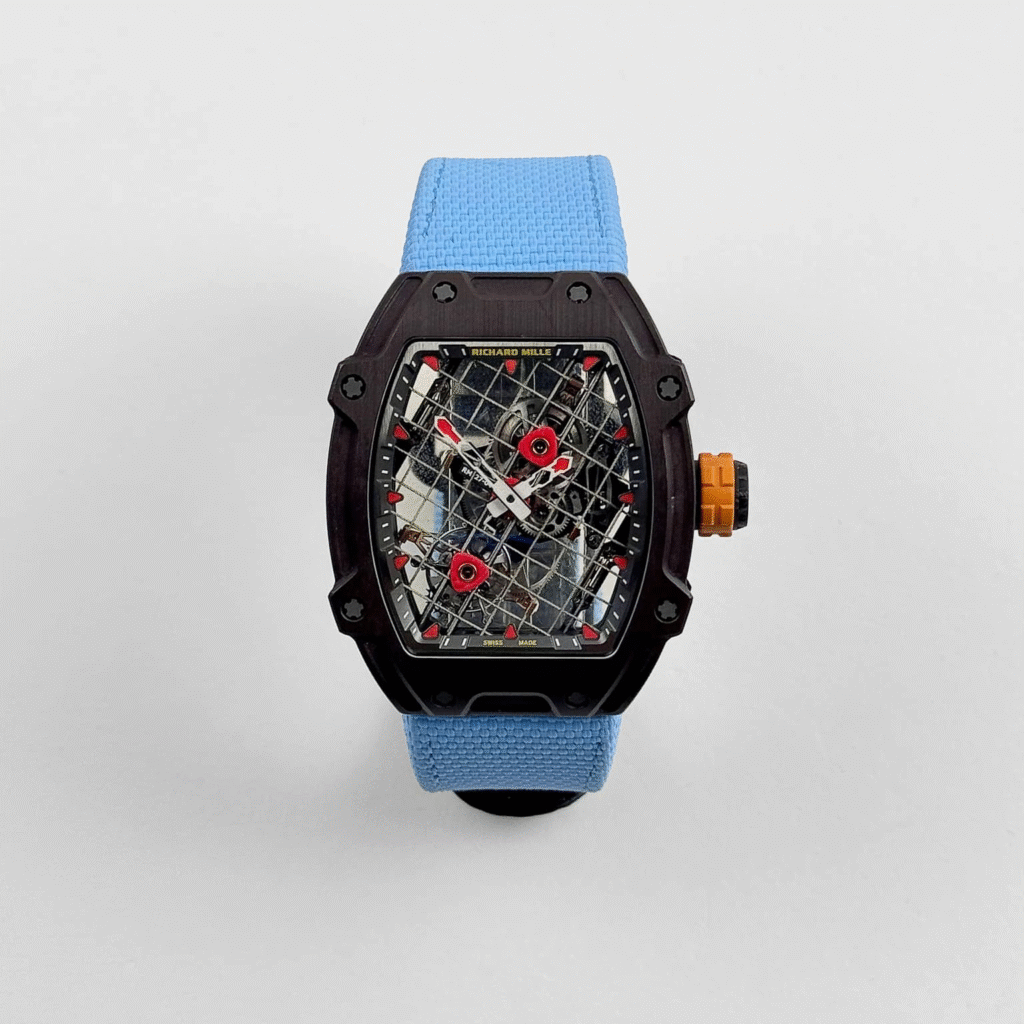

The RM 27-04 Tourbillon, created for Rafael Nadal’s 10th anniversary partnership with Richard Mille, represents the pinnacle of shock-resistant watchmaking.

The movement is suspended within the case via a single braided steel cable measuring just 0.27mm in diameter—woven like tennis racquet strings into an 855-square-millimeter mesh. The entire movement “floats” on this cable network, held in place by two tensioners crafted from PVD-treated 5N gold.

This cable-suspension system enables the movement to withstand accelerations exceeding 12,000 g’s—a record for Richard Mille at the time. For perspective:

| Force Comparison | G-Force |

|---|---|

| Fighter jet combat maneuvers | ~9 g |

| Formula 1 crash deceleration | ~140 g |

| 155mm artillery shell electronics | 15,500 g |

| Richard Mille RM 27-04 resistance | 12,000 g |

| Richard Mille RM 27-05 resistance (2024) | 14,000 g |

The latest RM 27-05 (released 2024) weighs just 11.5 grams without strap yet resists 14,000 g’s—achieved through five years of Carbon TPT B.4 case development. This surpasses the shock resistance of most military electronics while weighing less than three sheets of paper.

Weightlessness as a Complication: Creating the World’s Lightest Mechanical Tourbillons

Traditional watchmaking celebrates weight as a quality indicator. Heavier watches signal precious metals and solid construction. Richard Mille inverted this paradigm completely.

The RM 027 (original Nadal watch, 2010) weighed 19.8 grams including strap—lighter than many quartz watches. The progression demonstrates relentless engineering:

- RM 027 (2010): 19.8g total weight

- RM 27-01 (2013): 18.83g, introduced cable suspension

- RM 27-02 (2015): 19g, Quartz TPT case

- RM 27-04 (2020): 30g including strap, 12,000 g resistance

- RM 27-05 (2024): 11.5g without strap, 14,000 g resistance

This weight reduction doesn’t compromise movement architecture. The tourbillons remain fully functional, manually-wound mechanical movements with 38–48 hour power reserves. Achieving this requires titanium baseplates, skeletonized bridges, and extreme material optimization impossible with traditional watchmaking materials.

The Variable Geometry Rotor: Adapting Automatic Winding to User Lifestyle

Richard Mille’s Variable Geometry Rotor represents practical innovation addressing real-world wearing conditions. Traditional automatic movements use fixed-weight rotors optimized for average activity levels. Highly active users (athletes) overwind the mainspring, creating excessive tension. Sedentary users underwinding results in poor timekeeping.

The Variable Geometry rotor includes two adjustable weights that can be repositioned to alter rotor inertia:

- Sport setting: Lower inertia for active wearers (prevents overwinding)

- Office setting: Higher inertia for sedentary lifestyles (ensures adequate winding)

- Balanced setting: Middle position for mixed activity

This seemingly simple complication required extensive R&D and manufacturing precision. The adjustment mechanism must remain secure during high-G impacts while remaining adjustable by the wearer—engineering challenges traditional manufactures never addressed because they assumed watches would be removed during physical activity.

Comparison: Richard Mille Finishing vs. Patek Philippe Hand-Finishing

| Finishing Aspect | Traditional (Patek Philippe) | Richard Mille |

|---|---|---|

| Surface Treatment | Hand-polished, Geneva stripes | Sandblasted, micro-blasted titanium |

| Philosophy | Maximum shine and reflection | Function-first, weight reduction |

| Edge Work | Beveled, polished angles | Chamfered, matte surfaces |

| Decoration | Côtes de Genève, perlage | Skeletonization, exposed mechanics |

| Labor Hours | 200+ hours hand-finishing | 150+ hours CNC programming + machining |

| Weight Priority | Substantial = quality | Minimal = performance |

Neither approach is “better”—they serve different philosophies. Patek Philippe finishing celebrates centuries of hand-craft tradition. Richard Mille finishing prioritizes material efficiency and functional performance.

The Psychology of Price: Why Do They Cost $300,000+?

Production Numbers: Fewer Than 6,000 Watches Per Year

Richard Mille’s pricing begins with deliberate scarcity. The brand produces approximately 5,000–5,700 watches annually—compared to Rolex’s estimated 1,000,000 and Patek Philippe’s 60,000.

In 2024, Richard Mille achieved approximately CHF 1.55 billion ($1.77 billion USD) in revenue from just 5,700 watches, averaging approximately $310,000 per piece. This represents one of the highest average selling prices in luxury watchmaking—surpassing even Patek Philippe’s traditional dominance.

Limited production isn’t artificial scarcity—it reflects genuine manufacturing constraints:

- Complex materials require specialized facilities and equipment

- High rejection rates limit viable output

- Each watch requires extensive hand-assembly and testing

- Quality control standards eliminate marginal pieces

Many individual references are produced in runs of just 50–150 pieces, creating secondary market premiums where certain models trade for 150–300% above retail.

The “Billionaire’s Handshake”: The Watch as Ultimate Entry Ticket

Richard Mille watches function as visual wealth signals in elite social contexts. The distinctive tonneau case shape remains recognizable across rooms—unlike round Patek Philippe or Rolex models that require close inspection.

Wearing a Richard Mille immediately communicates:

- Net worth exceeding $10 million (minimum to rationally justify the purchase)

- Insider access (many models require pre-existing relationships with boutiques)

- Cultural sophistication (appreciation for avant-garde design and engineering)

- Athletic/adventurous lifestyle (the watches are designed for active wear)

This social signaling creates self-reinforcing demand. As more high-net-worth individuals recognize the brand, owning one becomes increasingly valuable for networking and social positioning—independent of horological merit.

R&D Costs vs. Material Costs: Paying for the Prototype

Traditional watchmaking amortizes R&D across large production runs. Rolex develops a movement once, then manufactures hundreds of thousands of copies. Richard Mille operates inversely—extensive R&D for limited production.

The RM 004 split-seconds chronograph required six years of development before the first watch shipped. The cable-suspension system for the RM 27 series demanded three years of prototyping before achieving 12,000 g resistance. Carbon TPT B.4 (used in the RM 27-05) required five years of materials research.

When you purchase a Richard Mille, you’re funding:

- Materials science research and development

- Partnership costs with aerospace suppliers (NTPT, Saint-Gobain)

- Prototype failures and manufacturing learning curves

- Extremely low production volumes limiting economies of scale

The Marketing Strategy: “Worn During Play, Not After”

The Ambassador Difference: Active Competition vs. Ceremonial Endorsement

Richard Mille’s ambassador strategy fundamentally differs from traditional luxury watch endorsements. Rolex pays Roger Federer to wear their watches during press conferences and award ceremonies—after matches conclude. Richard Mille pays Rafael Nadal to wear their watches during actual competition.

This distinction matters profoundly:

- Rafael Nadal wears the RM 27-series during Grand Slam finals

- Bubba Watson wore an RM 038 while winning the Masters (golf)

- Yohan Blake (Olympic sprinter) wears Richard Mille during 100m races

- Felipe Massa (F1 driver) wears Richard Mille during racing

These aren’t staged photo opportunities—they’re genuine performance validations. When Nadal wins a Grand Slam wearing an RM 27-04, the watch has survived hundreds of serves generating forces exceeding 4 g’s per impact.

F1 Partnerships: Ferrari and McLaren as Brand Identity Extensions

Richard Mille’s partnerships with Ferrari and McLaren extend beyond typical sponsorships. The brands collaborate on material science—NTPT’s composite expertise serves both Formula 1 chassis development and watch case manufacturing.

The RM 11-03 McLaren Automatic Flyback Chronograph features:

- McLaren Papaya Orange Quartz TPT® integrated into Carbon TPT® case

- Pushers and crown in McLaren signature orange

- Titanium pusher guards referencing F1 suspension components

- Marketing imagery showing the watch alongside actual McLaren F1 cars

This positioning reinforces Richard Mille’s core narrative: these are racing machines for the wrist, not dress watches for boardrooms.

Visibility and Recognition: The Distinctive Tonneau Shape

The tonneau (barrel) case shape represents brilliant marketing disguised as design innovation. Round watches dominate luxury watchmaking because they’re easier to manufacture and traditionally elegant. Richard Mille’s tonneau shape:

- Remains instantly recognizable across rooms

- Cannot be confused with Rolex, Patek Philippe, or Audemars Piguet

- Signals brand knowledge (only enthusiasts recognize RM)

- Creates visual distinctiveness in crowded social contexts

This shape recognition enables the “billionaire’s handshake”—two Richard Mille owners recognizing each other’s watches across a gala or business conference, immediately establishing social connection and shared values.

Market Performance & Investment Analysis (2025)

Retail vs. Secondary Market: Understanding Premiums and Depreciation

Richard Mille secondary market performance varies dramatically by model:

Models Trading Above Retail:

- RM 27-series (Nadal collaboration): +50% to +150%

- Limited editions (<50 pieces): +80% to +300%

- Discontinued references in excellent condition: +40% to +100%

Models Trading At or Below Retail:

- Entry-level automatic time-and-date: -10% to +15%

- Recent releases without celebrity association: -5% to +20%

- Models with production exceeding 500 units: -15% to +10%

The “Bubba Watson” and “Baby Nadal” Investment Curve

Certain references have generated exceptional returns:

- RM 038 Bubba Watson (2011): $300,000 retail → $750,000+ secondary market (2025)

- RM 27-04 Rafael Nadal (2020): $1,050,000 retail → $1,400,000–$1,800,000 secondary (2025)

- RM 56-02 Sapphire Tourbillon (2014): $2,020,000 retail → $2,800,000+ secondary (2025)

However, these represent outliers rather than norms. Most Richard Mille watches appreciate modestly (10–30% over 5 years) or depreciate slightly (-10% to +5%).

Liquidity Risks: Why Selling a $500k RM Is Harder Than Selling a $50k Rolex

The ultra-luxury segment faces genuine liquidity constraints:

Challenges selling Richard Mille:

- Extremely limited buyer pool (fewer than 100,000 people globally can afford $300,000+ watches)

- Authentication complexity (sophisticated counterfeits exist)

- Market volatility (prices fluctuate based on celebrity associations and social trends)

- Transaction costs (auction houses charge 15–25% commissions)

A $50,000 Rolex Submariner has millions of potential buyers globally. A $500,000 Richard Mille has perhaps 10,000 qualified buyers worldwide—and most already own multiple Richard Milles.

This creates a paradox: Richard Mille watches are simultaneously excellent stores of value (they don’t depreciate like cars) and poor liquid assets (you can’t quickly convert them to cash without significant discounts).

The Verdict: Where Marketing Ends and Engineering Begins

For the Collector: When Is an RM a “Must-Have”?

Richard Mille deserves consideration if:

- You appreciate materials science and aerospace engineering applied to watchmaking

- You genuinely wear watches during physical activity and value shock resistance

- You want a watch that visually signals wealth and insider knowledge

- You collect modern haute horlogerie rather than traditional complications

- You understand you’re buying engineering innovation, not finishing craftsmanship

Richard Mille is inappropriate if:

- You prioritize traditional hand-finishing and Geneva Seal standards

- You view watches primarily as investment vehicles (liquidity risks are real)

- You prefer understated luxury over visual distinctiveness

- You cannot comfortably afford 10–20% annual depreciation on a $300,000+ purchase

- You expect universal recognition (many people won’t recognize the brand)

For the Investor: Risks and Rewards in Hyper-Luxury

Investment advantages:

- Limited production ensures scarcity

- Celebrity associations create cultural cachet

- Materials innovation differentiates from traditional brands

- Secondary market exists with established pricing

Investment risks:

- Limited buyer pool reduces liquidity

- Fashion trends can shift rapidly

- Authentication complexity enables sophisticated counterfeits

- Economic downturns disproportionately impact ultra-luxury segments

Final Conclusion: A Fusion of Both Worlds

Richard Mille succeeds as both marketing genius and horological innovator—not despite the contradiction, but because of it.

The marketing brilliance lies in positioning watches as performance instruments worn by billionaire athletes—creating aspirational desire divorced from traditional luxury signaling. The horological achievement lies in genuine materials science innovation and shock-resistance engineering that traditional manufactures cannot replicate.

Critics who dismiss Richard Mille as “pure marketing” ignore the Carbon TPT®, the 12,000 g shock resistance, and the aerospace-grade manufacturing. Defenders who claim “pure horology” ignore the deliberate scarcity, the celebrity endorsements, and the social signaling value.

The truth: Richard Mille represents 21st-century luxury watchmaking—where engineering meets exclusivity, where aerospace materials replace gold finishing, and where performance during competition matters more than elegance in boardrooms.

Whether that’s worth $300,000+ remains entirely personal—but the achievement itself is undeniable.